Explore our collection of fly ash brick machines, Fully Automatic Paver block machines, and Automatic Vibrator Machine, renowned worldwide for their high quality, innovative technology, and global export excellence.

| Technical Specification | |

|---|---|

| MACHINE | Body Heavy Duty 1 Piece : M.s Fabricated Stationary Chassis Of Angles, Channels And Sheet Fitted With Hydraulic Jacks For Compression Of 4000 PSI Hydraulically Operated Power Pack With10 Hp Ac Motor, Sweep, Oil Cooling System, And Plate Vibrating System With 2 Hp Vibrator Power Pack High Pressure, Low Pressure Pump, Control Valve, Relieve Valve, Pcm, Pressure Gauge, Pipe Line, Oil Tank Capacity 400 Litter, Plc Etc. |

| CAPACITY | Solid Blocks - 2-3 Pcs. in One Operation. Production : 3-4000 Pcs/8 Hrs |

| SIZE | 12" x 8" x 6" |

| TOTAL POWER | Total Power Required : 25 HP |

| MAN POWER | Total : 8 to 10 ( 1 person skilled ) |

| FACILITY | Facility Single Feeder Facilities For Production of Fly Ash Brick Superior Vibration in Brick Press, Colour Feeder for the Top Layer of Paver Block. |

| PAN MIXER | Pan mixer 2 Pieces : of 1500 mm diameter fabricated with structural mild steel with replicable inner fitted with 10 HP, oil fitted reduction gear box feeding hopper with a capacity to mix 350 kg raw material. |

| CONVEYOR BELT | Belt Conveyor 1 Piece: to shift mixed activated raw material from pan mixer to the feeder bin of the press. The 18 feet rubber conveyor belt is mounted on a structurally fitted with 2 HP motor. |

| PALLET TRUCK | Pallet Truck 2 Piece: To Lift The Raw Material And Stocks To One Place To Another Place, This Is A Manually Operated On Structural Mild Steel Chassis With Tires. |

| NOTE | With Toolbox Free |

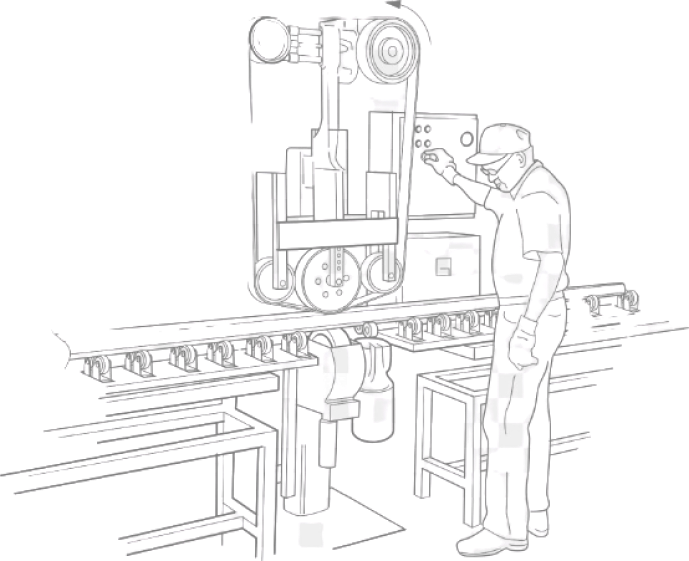

This automatic solid block making machine has a 4000 PSI hydraulic jack and can produce 2/3 hollow blocks in a single operation. It takes 25 horsepower. This solid block making machine can produce solid blocks in a variety of sizes, including 1 2 "x 8" x 6 ", and can produce 3,000 to 4,000 blocks in approximately 8 hours. 1 Conveyor Belt is used to transport mixed activated raw material from the pan mixer to the press's feeder bin.

The oil capacity of this machine is approximately 400 liters. Moving raw materials and inventory from one location to another requires two pallet trucks, each manually operated with a mild steel frame with tires. Using hydraulic oil as the working medium, the operation of the block making machine is completed without waste.

Solid blocks are one of the most common types of concrete products used in construction. Portland cement, water, sand, and gravel, sawdust, expanded clay are mixed to make solid blocks. Solid blocks can be constructed in a variety of ways and one is made from a solid block making machine.

The most significant building materials for making walls are solid blocks. Such blocks are used in walls because of their characteristics, availability, and affordability. Solid blocks, unlike injected concrete, are extremely resistant to cracking and collapsing at extreme temperatures. Termites and vermin are unable to spread through solid blocks, extending the life of the wall.

These blocks require an advanced solid block making machine manufacturing solid blocks. A solid block making machine is one of the construction machines that allow for the production of various sizes of solid blocks. This block making machine includes numerous important customizations. Our block making machine uses hydraulic pressure and vibration-based feeding systems to produce each block with extreme accuracy and precision.

Solid block making machines have different specifications in terms of output, maintenance costs, prices, running costs, and so on.

Let's take a closer look at the solid block making machine and its manufacturing process.

ISO Certified Company

Best Quality

24/7 Support

Client Satisfaction

ISO Certified

Company

24/7

Support

Top Quality

Machinery

Get Your Free Quote Now

Designed for High-Volume, High-Quality Block Production