| Technical Specification | |

|---|---|

| MACHINE | Body : Heavy Duty 1 Piece : M.s Fabricated Stationary Chassis Of

Angles, Channels And Sheet Fitted With Hydraulic Jacks For Compression Of 4000 PSI

Hydraulically Operated Power Pack With10 Hp AC Motor, Sweep, Oil Cooling System, And

Plate Vibrating System With 2 Hp Vibrator, Cycle Period 20 seconds to give output. Power Pack : High Pressure, Low Pressure Pump, Control Valve, Relieve Valve, PCM, Pressure Gauge, Pipe Line, Oil Tank Capacity 400lts PLC : Electronics pressure control volume system. MS steel sensor system with Auto stop facility. Hydraulic speed control system. Vibrator control system. - Emergency Button,Stroke calculator, Delay Timer, LED & Display.Facility to Operate the Machine in Fully Auto., Semi Auto.& Manually. |

| CAPACITY | Paver Block - 10 Pcs. in One Operation. Production : 12-15000 Pcs/8 Hrs |

| DESIGN | Zic Zac, I-Shape, Hexagone, Etc. |

| TOTAL POWER | Total Power Required : 32 HP |

| MAN POWER | Total : 8 to 10 ( 1 person skilled ) |

| Facility | Facility Double Feeder Facilities For Production of Paver Block Superior Vibration in Brick Press. |

| PAN MIXER | Pan mixer 2 Pieces : of 1500 mm diameter fabricated with structural mild steel with replicable inner fitted with 15 HP, oil fitted reduction gear box with a capacity to mix 450 kg raw material. |

| CONVEYOR BELT | Belt Conveyor 1 Piece: to shift mixed activated raw material from pan mixer to the feeder bin of the press. The 18 feet rubber conveyor belt is mounted structurally fitted with 2 HP motors. |

| PALLET TRUCK | Pallet Truck 2 Piece: To Lift The Raw Material And Stocks To One Place To Another Place, This Is A Manually Operated On Structural Mild Steel Chassis With Tires. |

| COLOR MIXER | For the purpose of making first layer of Paver Block Power 2HP |

| NOTE | With Toolbox Free |

| Technical Specification | |

|---|---|

| MACHINE |

Body : Heavy Duty l Piece : M.s Fabricated Stationary Chassis Of Angles, Channels And Sheet Fitted With Hydraulic

Jacks For Compression Of 3500 PSI Hydraulically Operated Power Pack With10 Hp Ac Motor, Sweep, Oil Cooling

System, And Plate Vibrating System With 2 Hp Vibrator. Power pack :High Pressure, low pressure pump, control valve, relieve valve,PCM,Pressure gauge, Pipe Line, Oil Tank Capacity 400lts PLC:Electronics pressure control volume system. MS steel sensor system with Auto stop facility. Hydraulic speed control system. Vibrator control system. - Emergency Button,Stroke calculator,Delay Timer,LED & Display.Facility to Operate the Machine in Fully Auto., Semi Auto.& Manually. |

| CAPACITY | Paver Block - 8 Pcs. in One Operation. Production : 10-12000 Pcs/8 Hrs |

| DESIGN | Zic Zac, I-Shape, Hexagone, Etc. |

| TOTAL POWER | Total Power Required : 27 HP |

| MAN POWER | Total : 8 to 10 ( 1 person skilled ) |

| FACILITY | Facility Double Feeder Facilities For Production of Paver Block Superior Vibration in Brick Press. |

| PAN MIXER | Pan mixer 2 Pieces : of 1500 mm diameter fabricated with structural mild steel with replicable inner fitted with 10 HP, oil fitted reduction gear box with a capacity to mix 400 kg raw material. |

| CONVEYOR BELT | Belt Conveyor 1 Piece: to shift mixed activated raw material from pan mixer to the feeder bin of the press. The 18 feet rubber conveyor belt is mounted structurally fitted with 2 HP motors. |

| PALLET TRUCK | Pallet Truck 2 Piece: To Lift The Raw Material And Stocks To One Place To Another Place, This Is A Manually Operated On Structural Mild Steel Chassis With Tires. |

| COLOR MIXER | For the purpose of making first layer of Paver Block Power 2HP |

| NOTE | With Toolbox Free |

| Technical Specification | |

|---|---|

| MACHINE |

Body : Heavy Duty 1 Piece : M.s Fabricated Stationary Chassis Of Angles, Channels And Sheet Fitted With Hydraulic

Jacks For Compression Of 3000 PSI Hydraulically Operated Power Pack With7.5 Hp Ac Motor, Sweep, Oil Cooling

System, And Plate Vibrating System With 1 Hp Vibrator. Power pack : High Pressure,low pressure pump, control valve, relieve valve,PCM,Pressure gauge, Pipe Line, Oil Tank Capacity 350lts PLC : Electronics pressure control volume system. MS steel sensor system with Auto stop facility. Hydraulic speed control system. Vibrator control system. - Emergency Button, Stroke calculator, Delay Timer, LED & Display.Facility to Operate the Machine in Fully Auto., Semi Auto.& Manually. |

| CAPACITY | Paver Block - 4 Pcs. in One Operation. Production : 5-7000 Pcs/8 Hrs |

| DESIGN | Zic Zac, I-Shape, Hexagone, Etc. |

| TOTAL POWER | Total Power Required : 20 HP |

| MAN POWER | Total : 8 to 10 ( 1 person skilled ) |

| FACILITY | Facility Double Feeder Facilities For Production of Paver Block Superior Vibration in Brick Press |

| PAN MIXER | Pan mixer 1 Pieces : of 1800 mm diameter fabricated with structural mild steel with replicable inner fitted with 7.5 HP, oil fitted reduction gear box with a capacity to mix 400 kg raw material |

| CONVEYOR BELT | Belt Conveyor 1 Piece: to shift mixed activated raw material from pan mixer to the feeder bin of the press. The 18 feet rubber conveyor belt is mounted structurally fitted with 2 HP motors. |

| PALLET TRUCK | Pallet Truck 2 Piece: To Lift The Raw Material And Stocks To One Place To Another Place, This Is A Manually Operated On Structural Mild Steel Chassis With Tires. |

| COLOR MIXER | For the purpose of making first layer of Paver Block Power 2HP |

| NOTE | With Toolbox Free |

Over the years, there has been an increase in the use of paver block making machines in construction. We in the technical department are aware of the situation, we are continuously looking for ways to build cutting-edge machinery for manufacturing blocks.

Paver block demand is increasing as a result of the need for paver block machines. Paver blocks are one of the most often used for outside pavement applications. These blocks have a beautiful appearance, are cozy to walk on, are quite strong, and are simple to keep clean.

The raw materials needed to create paver blocks include water, cement, concrete admixture, and crushed stone dust. Therefore, a fully automatic paver block making machine is required for making heavy-duty blocks.

The most crucial element in the creation of paver blocks is a sophisticated block-making machine with a high production capacity and low maintenance needs. Steel Land Machinery Works is a well-known paver block making machine manufacturer in India.

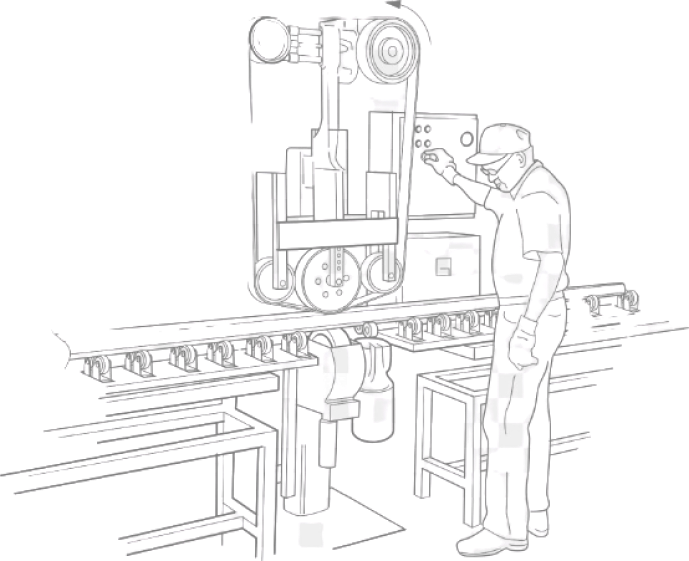

Our hydraulic paver block making machine can generate many different sized paving blocks and interlocking blocks in a short period of time. We manufacture paver block machines in three different production capacities.

ISO Certified Company

Best Quality

24/7 Support

Client Satisfaction

A block making machine is specifically designed machine to produce various types of concrete blocks. It can be used to make blocks of various shapes and sizes by switching out moulds. Concrete hollow blocks, paver blocks, solid blocks, interlocking blocks, and curbstones are some of its examples.

A paver block making machine works by vibrating and compressing the concrete. They have a hopper where they receive and store fresh cement for the production of the blocks. After that, the appropriate amount of material is poured to fill the mould. A pressure machine is then used to shape the paver block. After that, it is moved to sunlight to dry properly.

It is determined by the type of paver block making machine used and the number of hours worked by the construction company per day. Steel Land Machinery Works, a 70-ton paver block making machine can produce 2500 blocks per day, whereas a 90-ton machine can produce 3000 bricks in 8 hours. In addition, a 100 Ton machine can produce 3500 Bricks and Blocks in 8 hours.

We are the Leading Brick Making Machinery

Company in India.

43 Reviews