Two different kinds of construction blocks are concrete and fly ash bricks. They are made differently and with various materials. Bricks with fly ash are created from industrial waste. It resembles recycling somewhat! The byproduct of burning coal, fly ash, is used to make these bricks. After that, a unique device known as a fly ash brick machine is used to mould them into bricks. Conversely, the ingredients of concrete bricks are aggregate, which is just a fancy term for tiny pieces of stone, and cement. After combining the ingredients, they are poured into moulds and let to solidify. Best fly ash bricks machine in India completes all of the pouring, mixing, and molding.

Raw Materials Used

1. Fly Ash Bricks

Fly ash is a powdery byproduct of coal-fired power plants. It is comparable to our brick cake’s flour! Fly ash must be mixed with water to form a paste, much as dough requires water. Lime and Gypsum provide the bricks tremendous strength and aid in maintaining their shape. Bricks are created by combining these materials and pressing them via a machine. After that, these bricks solidify and become usable.

2. Concrete Bricks

In the process of creating concrete bricks, the mixture is crucial. The primary component that holds everything together and gives bricks their hardness and durability is cement. The structure of the brick is added by adding small rocks or sand. That’s what gives it its strength! To make the mixture workable, a small amount of water is added. It facilitates the binding of aggregate and cement.

The Production Process

1. Fly Ash Bricks

It starts with a mixture of water and fly ash, an elegant phrase for particular sorts of dust. Then, this mixture becomes a paste the consistency of your preferred pancake batter. After that, the paste transforms into bricks by entering mould boxes. After that, the bricks indulge in a 24-hour steam bath. The bricks are left to harden and dry out, which takes about a week. The last stage is to wait.

2. Concrete Bricks

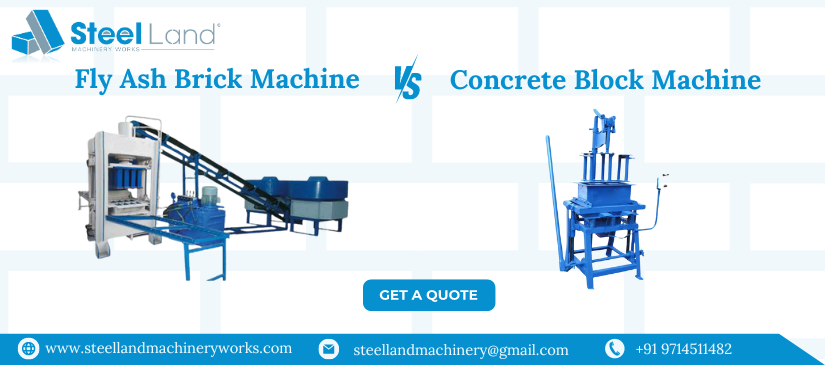

The fly ash brick machine and the concrete block machine are the two machines that rule the world of brick making. Although they can appear very similar at first look, let’s take a closer look and discover the differences between these two devices. Fly ash brick machines combine sand, lime, and gypsum with a unique kind of waste product called fly ash to create environmentally beneficial bricks. Conversely, concrete block machines use a cement, water, and aggregate mixture to produce sturdy concrete blocks.

Strength and Durability

1. Fly Ash Bricks

Bricks with fly ash are created from industrial waste. They become eco-friendly as a result, which is great news for our planet. Their greatest asset is their strength. They can withstand high pressure and are resistant to earthquakes. They can also keep buildings’ interior temperatures stable. They save a ton of electricity because of this!

2. Concrete Bricks

The three main ingredients of concrete bricks are cement, sand, and water. They are resilient to weather fluctuations, extremely sturdy, and able to withstand great pressure. However, concrete bricks aren’t very friendly to the environment, in contrast to fly ash bricks. They generate CO2 during manufacture and consume a lot of resources.

Conclusion

It is obvious that your unique needs and the specifications of your building project will play a major role in your decision between a fly ash brick machine and a concrete block machine. Compared to concrete bricks, fly ash bricks are lighter and hence easier to handle. Compared to fly ash bricks, concrete blocks are more robust and last longer.